Thermoprocessing Plants and Equipment

Due to our many years of experience, you can rely on our in-depth knowledge in the field of thermal process technology. Our knowledge, coupled with a high degree of preparedness to always use state-of-the-art technology, has paved the way for us as the innovation leader in the construction of industrial furnace plants and equipment for international industries like hard metal powder industry, ceramic industry or grinding industry.

Through the use of simulation tools for the calculation of flow phenomena by means of finite element methods, so-called CFD simulations, results already calculated in the development phases of projects can be compared with practical empirical values. In order to achieve our goals, the interdisciplinary teamwork of experts from many areas of general mechanical engineering, such as process engineering, CAD design, control technology and fluid mechanics, is necessary. The use of only the highest quality components and insulation materials finally rounds off the image of modern furnace technology at the highest level.

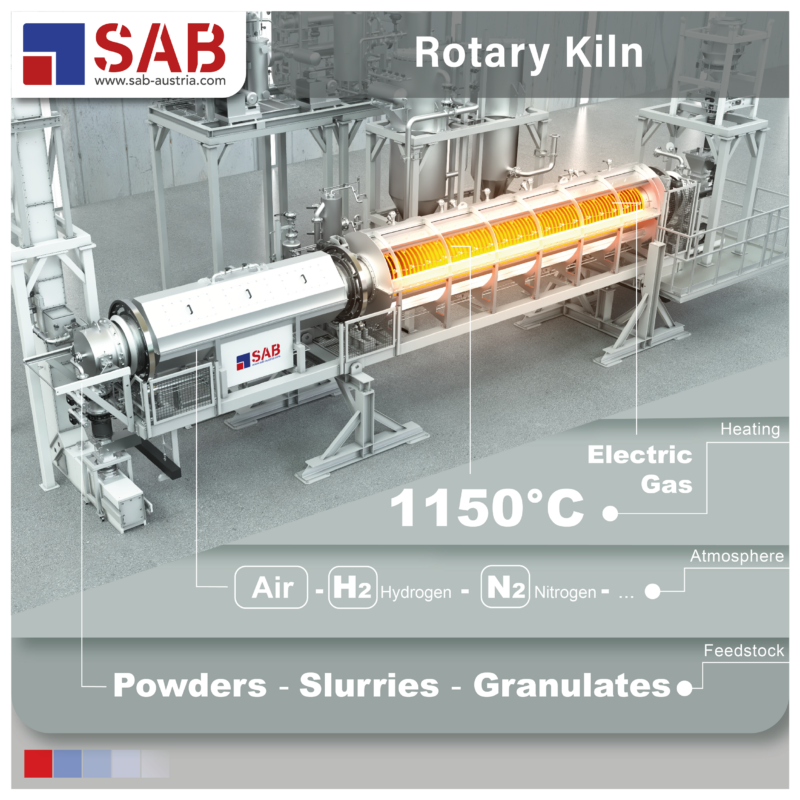

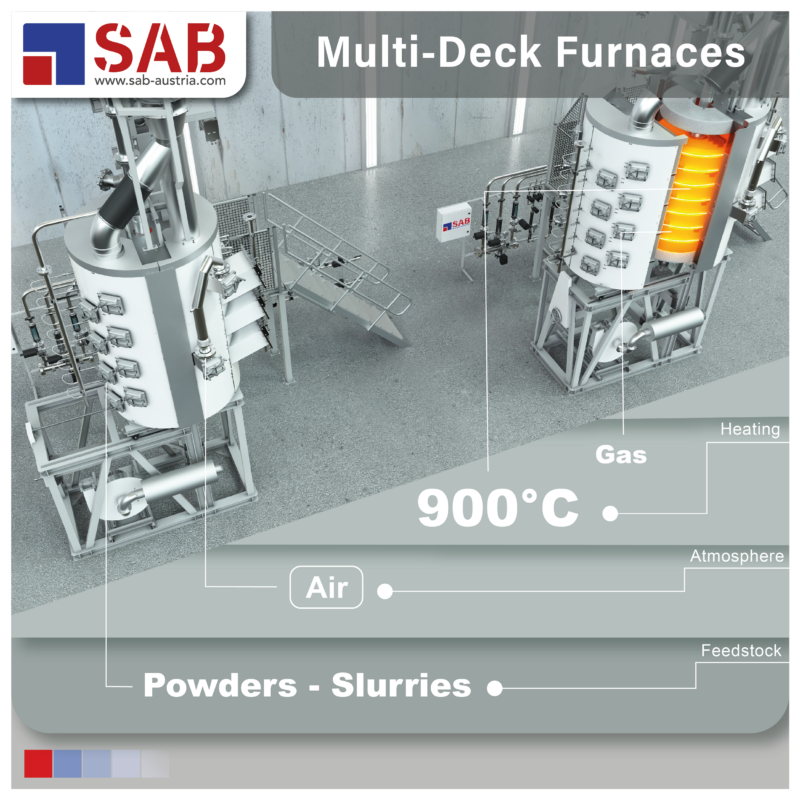

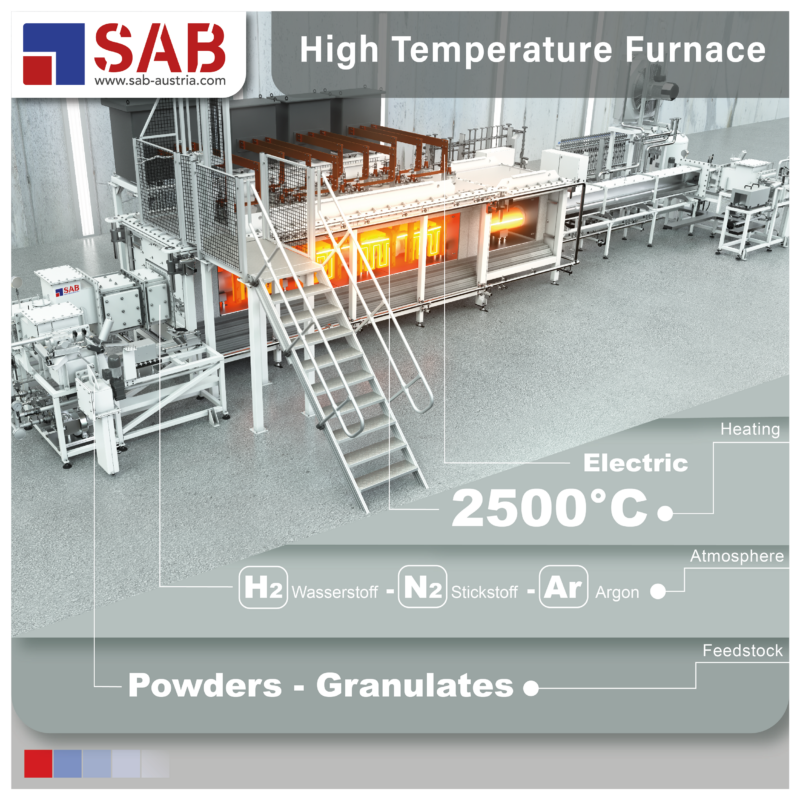

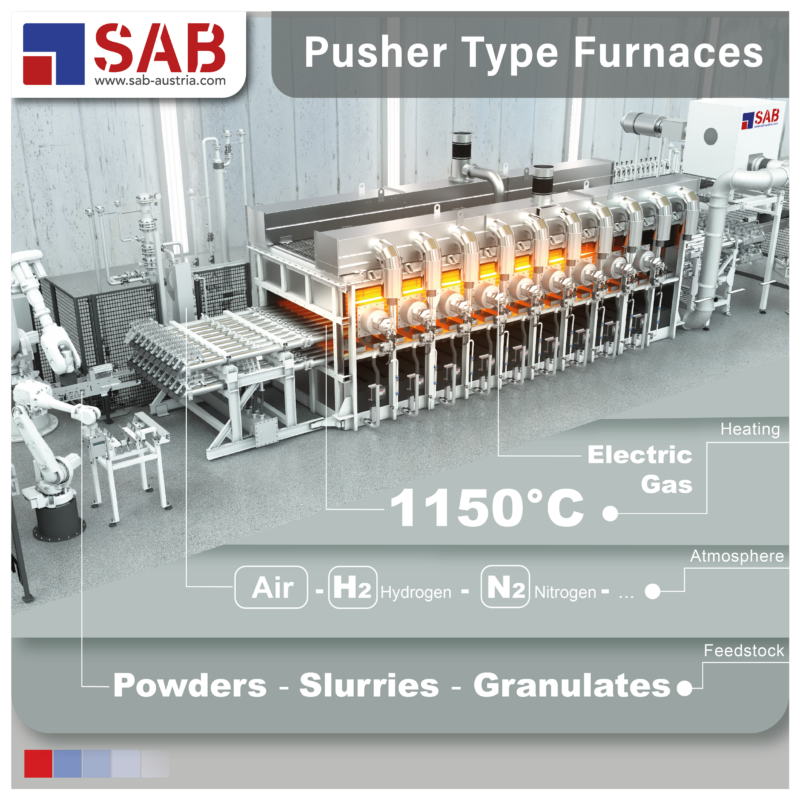

We are also happy to be your partner for new requirements and products. Starting with the development of furnace systems in laboratory size, we offer you support towards a tailor-made furnace plant of industrial size for the following furnace types:

- High Temperature Furnaces up to 2.500°c

- Pusher Type Furnaces

- Multi Deck Ovens

- Recirculating Air Ovens

- Conveyor Belt Furnaces

- Batch Furnaces

- Rotary Kilns

Due to our expertise in automation technology and thermal process technology, these furnace types can also be supplemented by full or partial automation.